Guide on Choosing the Right Breather Valve for Managing Back Pressure Scenario

Revamped Article:

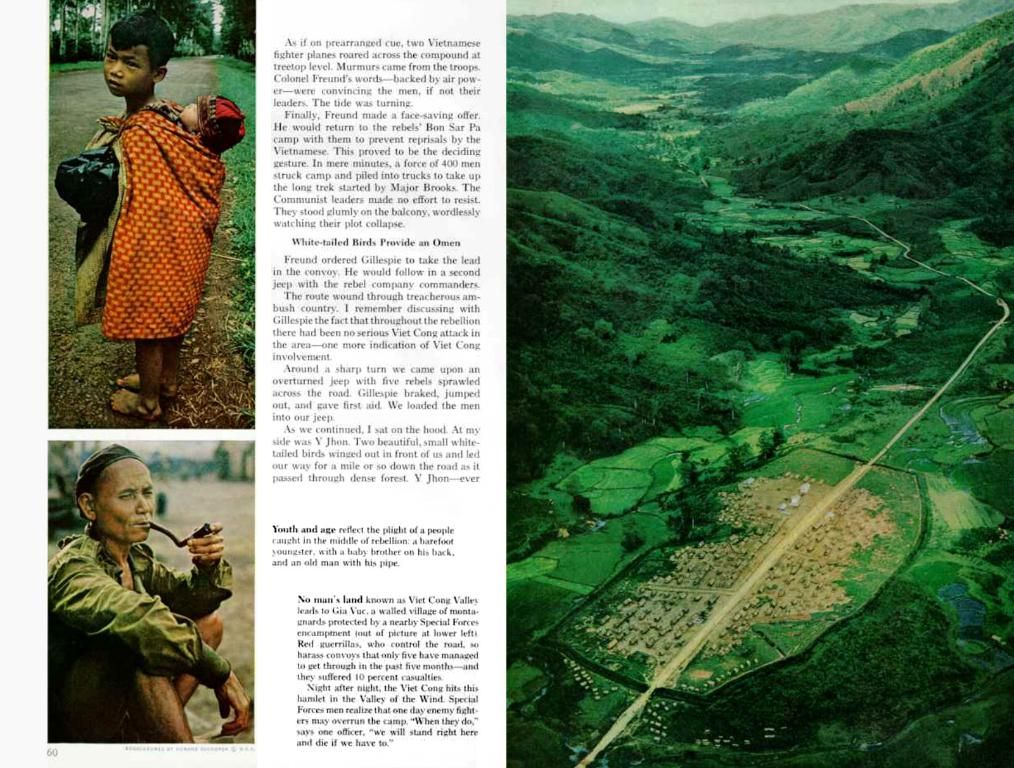

- rolled up sleeves grabs a cup of coffee Alright, mate, let's dive into the nuts and bolts of selecting the right pressure and vacuum relief valves (PVRV) for industrial storage tank applications. A recent query from one of our clients highlights a common issue when it comes to picking a breather valve. So, grab a brew and join me as we tackle this problem, discussing suitable solutions.

Project Summary

This project involves a storage tank for storing acetone with nitrogen gas, acting as an inert blanketing medium. The nitrogen is used to curb the contact between oxygen and acetone, thereby reducing the fire risk. The tank incorporates a pressure of 180 mbarg (positive pressure) and -10 mbarg (negative pressure) to cope with diverse inflow and outflow conditions.

The breather valve's discharge outlet links to a flare system that has a maximum back pressure of 65 mbarg, and the breather valve is stress-set at 90 mbarg. However, this exceeds what the process engineer designed for, potentially overpressuring the tank. Sadly, they didn't offer any viable solutions for the client, which led them to seek our help.

Tank Design

- Positive Setting Pressure: 180 mbarg

- Negative Setting Pressure: Set -10 mbarg

Client's Issue

- The back pressure stems from the breather valve discharge linking to the flare line.

- The tank design conditions are 180 mbarg and -10 mbarg.

Problem Dissection

The heart of the problem lies in the influence of back pressure. Traditional breather valve designs rely on weight or spring loading, and as back pressure increases, the actual opening pressure of the valve follows suit. Ordinarily, there's no back pressure when the breather valve vents to the atmosphere; however, in this project, due to the breather valve linking to the flare header, back pressure outside the normal range surfaced. This design doesn't support the breather valve functioning correctly at the preset 90 mbarg. Using a traditional breather valve in this case would result in the set point exceeding the tank's design pressure, raising the danger to the tank.

Our Proposed Solution

1. Back Pressure Reduction

We can lessen back pressure by amplifying the pipe size or moving the outlet port closer to the flare system.

2. Suitable Type of Breather Valve - Pilot-Operated PVRV

For general gravity or spring-loaded breather valves, if the setting value of 155 mbarg is upheld by other suppliers, when the back pressure decreases (back pressure range is 0~65mbarg), a higher opening pressure problem may occur. For instance, if the back pressure drops to 10mbarg, the opening pressure will be 155-10=145mbarg, which will surpass the safety setting value of the tank. Using a traditional breather valve would run the risk of exposing the tank to harm at the 90 mbarg pressure relief value.

It is suggested to opt for a pilot-operated pressure relief vacuum valve to enable relief at the 90 mbarg set point under varying back pressure conditions.

Why go for Pilot-Operated Pressure/Vacuum Relief Valve

The primary reason why a pilot-operated pressure vacuum relief valve (POPVRV) prevents the main valve from being affected by back pressure is its unique design. The main valve is independent of back pressure due to the pilot valve controlling its operation. The opening and closing of the valve are insulated from the tank pressure or external backpressure by the pilot valve.

1. Backpressure independence

Traditional weight-loaded or spring-loaded breather valves depend on the physical weight of the valve disc or the spring force. When back pressure increases, the total pressure necessary to open the valve also swells. In cases of significant back pressure, the actual opening pressure of the valve will be more than the set point. On the contrary, a pilot-operated PVRV exploits a separate control chamber to manage the valve's opening. Therefore, the opening pressure remains unaffected by changes in backpressure.

Pilot-Operated Pressure/Vacuum Relief Valve Mechanism

The pilot valve is a tiny valve that regulates the operation of the main valve. When the pressure or vacuum inside the tank reaches the set point, the pilot valve snaps open, releasing the pressure or vacuum in the main valve's chamber, and causing the main valve to open. This design guarantees that the main valve opens exactly at the set pressure without any delays due to variations in backpressure.

2. Lower Overpressure

Standard weight-loaded or spring-loaded PVRVs call for significant overpressure to fully open the valve, which can, in some cases, bring the tank pressure perilously close to the design limit. However, a pilot-operated PVRV can open and perform fully with lower overpressure, typically requiring only 10% to 15% overpressure to gain full flow. This diminishes pressure fluctuations within the tank and enhances the tank's overall safety.

3. Precise Pressure Management

Pilot-operated PVRVs offer you better control over the pressure and vacuum set points for your tank. Despite external backpressure, the pilot-operated breather valve maintains the main valve closed until the inner pressure reaches the set point, thereby averting problems such as premature or delayed opening due to superimposed backpressure, ensuring secure tank operation under intended pressure conditions.

4. Efficient Sealing

One notable advantage of the pilot-operated PVRV design is that it can maintain good sealing performance as it approaches the set pressure, preventing gas leakage. For example, by employing special sealing technology (such as air-cushioned sealing), the valve can stay sealed even as it nears the set pressure, which impedes premature gas leaks, reduces product loss, and aids in environmental protection.

5. Adaptive Flexibility

Pilot-operated PVRVs can be set up to address different pressure ranges and operating conditions as deemed fitting. For instance, you can customize the pressure set point and response time of the pilot valve according to your specific tank requirements. Additionally, you can utilize them in systems with oscillating backpressure, such as tanks connected to flare systems.

Summing Up

When selecting a suitable breather valve for storage tank applications, it's crucial to take both the system's design pressure and the impact of back pressure into account. A pilot-operated pressure/vacuum relief valve (POPVRV) offers significant advantages in coping with back pressure issues and ensuring safe operation under varying back pressure conditions. It is important, however, to be mindful of back pressure fluctuations when selecting a POPVRV and take necessary precautions, including lowering the set pressure, employing a back pressure control system, and implementing a monitoring system.

With this design and protection, you can effectively curtail the risk of overpressure due to back pressure fluctuations, ensuring the safety and stability of the tank during operation.

Should you require additional information on pilot-operated breather valves or other tank protection equipment, don't hesitate to peruse our website to download product catalogs or reach out to us directly. We're excited about collaborating with you to offer the finest solutions for your project.

Enrichment Data:Advantages of Pilot-Operated Pressure/Vacuum Relief Valves (POPVRVs) in Industrial Storage Tank Applications

Pilot-Operated Pressure/Vacuum Relief Valves (POPVRVs) offer several advantages in industrial storage tank applications, primarily in managing back pressure and ensuring secure and efficient operations:

- Back Pressure Management: - Isolation and Stabilization: POPVRVs use a pilot valve to isolate the main valve from external pressures, ensuring efficient sealing and preventing premature gas leaks. This design allows adaptable performance across different pressure ranges and operating conditions, such as systems with fluctuating backpressure[1].

- Pressure Control: - Minimal Pressure Override: By using a tiny pilot valve to control the operation of a larger main valve, POPVRVs deliver precision relief with minimal pressure override. This is crucial for maintaining stable internal tank conditions and avoiding overpressure issues[4].

- Reliability and Operational Performance: Stable and Responsive Control: Pilot-operated valves offer improved stability and responsiveness in managing pressure conditions, ensuring reliable performance for critical applications[4].

- Emissions Reduction and Energy Efficiency: - Reduced Venting: POPVRVs help stabilize internal tank conditions by limiting unnecessary venting, which leads to reduced energy consumption and the need for additional processing to compensate for losses. This translates to lower heating and cooling requirements, thereby reducing overall energy costs[1].

- Safety: - Protection Against Tank Deformation: POPVRVs prevent tank deformation and potential leaks by allowing air ingress under vacuum conditions and relieving excess pressure during tank filling or thermal expansion, ensuring environmental safety and operational stability[1].

In summary, POPVRVs are highly effective in tackling back pressure problems in industrial storage tanks by offering precise control, minimizing emissions, enhancing operational reliability, and ensuring environmental safety.

- The max back pressure of the flare system, to which the breather valve discharge is linked, is 65 mbarg, which exceeds the stress-set pressure of the breather valve at 90 mbarg, potentially leading to overpressure in the tank.

- In an attempt to address the client's issue, we propose using a pilot-operated pressure relief vacuum valve (POPVRV) in place of a traditional breather valve, as it operates independently of back pressure and can open precisely at the set pressure, regardless of changes in backpressure conditions.

- A pilot-operated PVRV offers advantages such as lower overpressure, precise pressure management, efficient sealing, and adaptive flexibility, as well as minimizing emissions, enhancing operational reliability, and ensuring environmental safety in industrial storage tank applications.