Textiles Professor Given NSF CAREER Grant

Bringing Sustainable Textile Manufacturing into the Future with Hemp: Professor Rong Yin's Ambitious Project

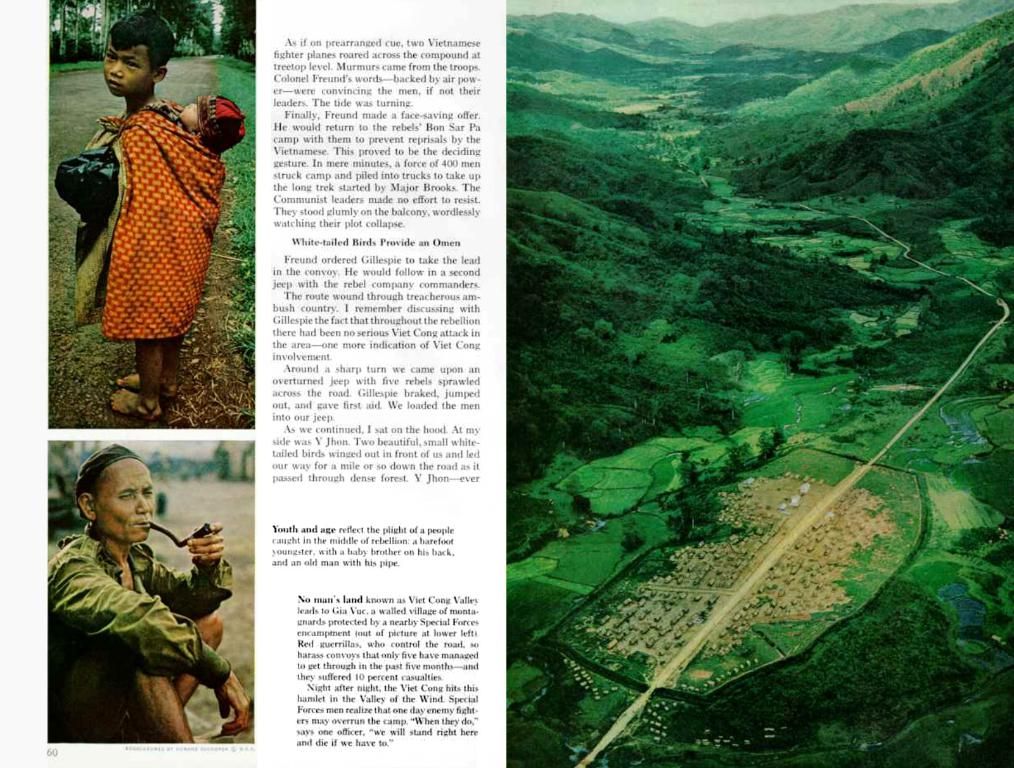

Meet assistant professor Rong Yin - the latest recipient of the National Science Foundation's (NSF) sought-after CAREER Award. This prestigious grant, part of the Early Career Faculty Development Program, is given to promising tenure-track assistant professors who show the potential to become leaders in their fields of research and education. Professor Yin stands to earn up to $500,000 by the grant's estimated end date in 2030.

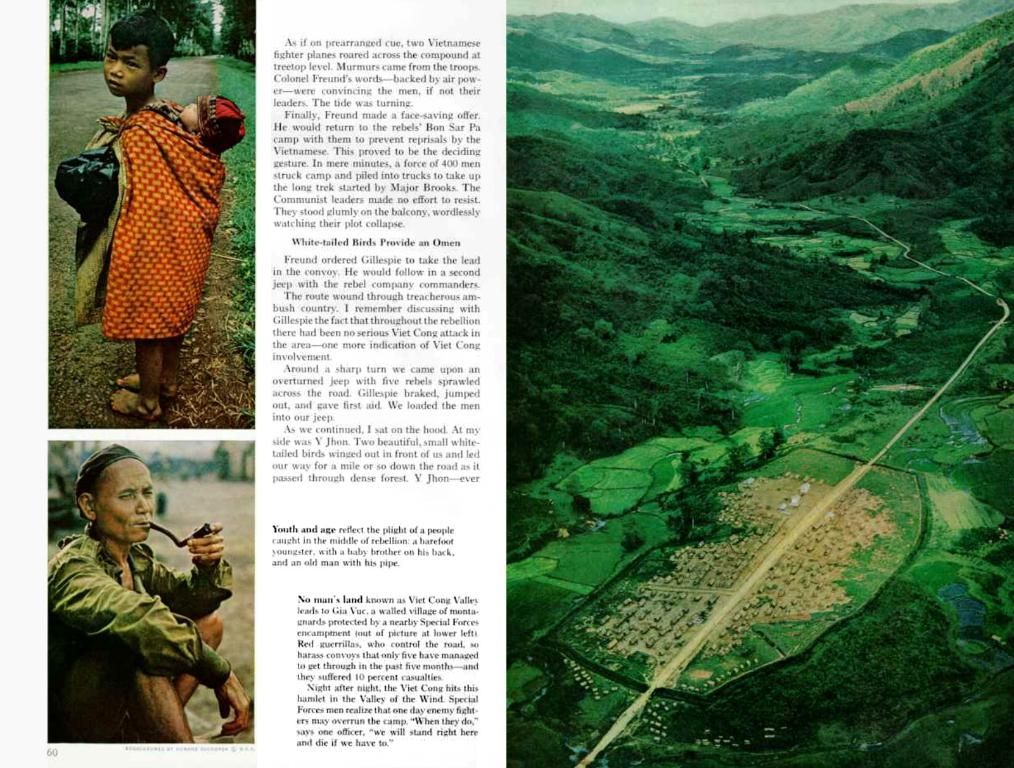

The Hemp Revolution in North Carolina: A New Era for Textiles

Just five years after hemp was legalized in North Carolina, the state boasted an impressive 1,500 hemp growers and 1,200 hemp processors. This surge in domestic availability has sparked the interest of textile scientists who see hemp fibers as potentially lowering the environmental impact compared to synthetics and cotton. The benefits? Hemp requires less water and avoids the petroleum found in most synthetic fibers, contributing to a greener textile industry (source).

However, hemp poses challenges when it comes to processing for textiles. Its natural stiffness, brittleness, and lack of crimp make it difficult to spin into yarn, resulting in inconsistent, low-performance strands. Moreover, many existing processing technologies struggle to handle these properties, leading to fiber breakage, poor twist uptake, and weak cohesion.

Many studies focus on chemical treatments or blending, with little attention given to system-level modifications, process optimization, or the sustainability of large-scale yarn production.

Yin's Innovative Approach: Overcoming Hemp's Challenges for a Greener Future

Using his CAREER grant, Professor Yin plans to tackle these issues with research in several key areas:

- Developing a modified spinning process that improves fiber cohesion for better yarn structure through the use of wetting.

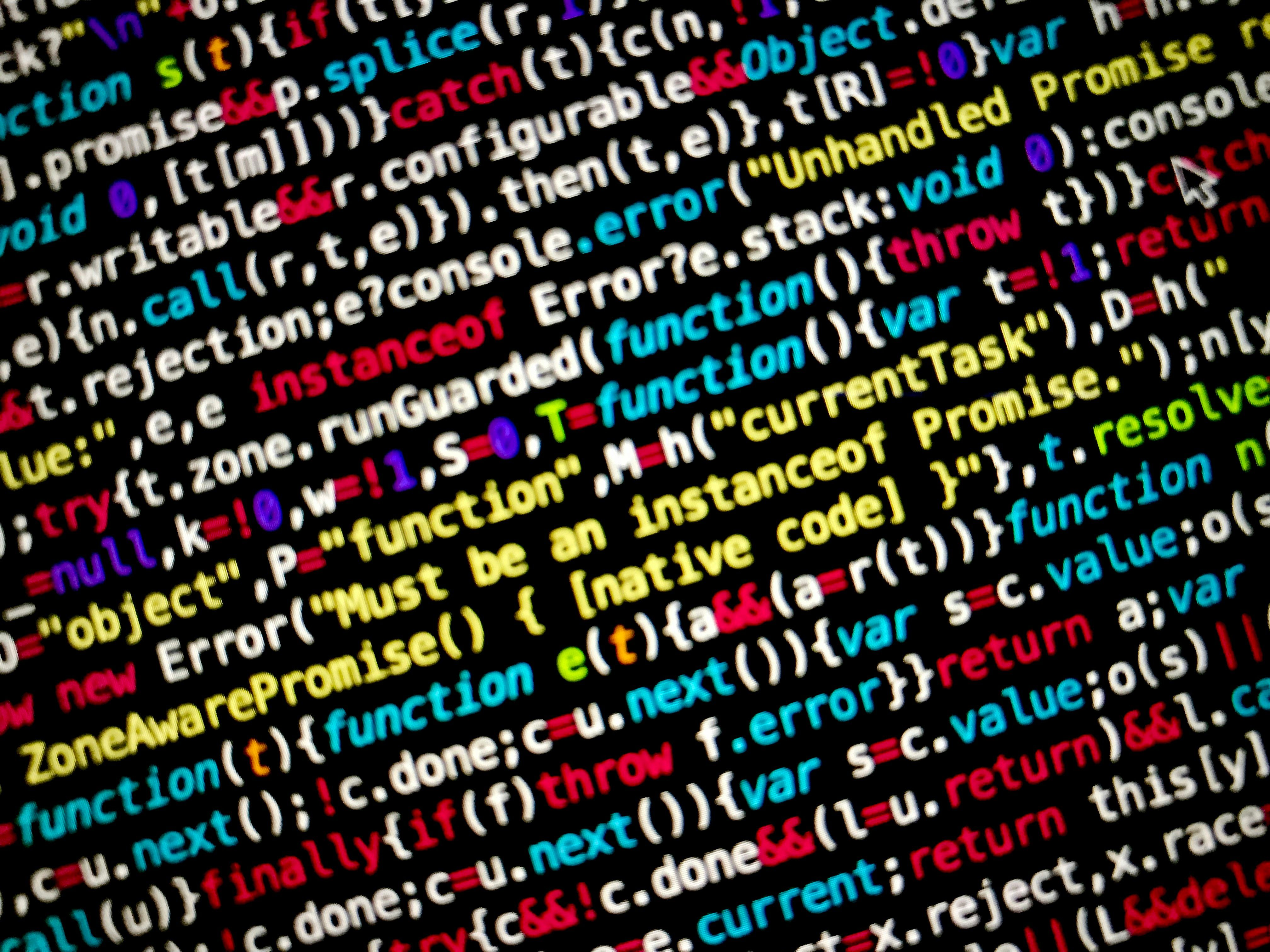

- Creating a data-driven framework for optimizing hemp yarn spinning, quantifying the relationships among processing parameters, spinning triangle, and yarn quality.

- Leveraging AI to analyze fiber dynamics in hemp yarns through micro-CT segmentation for detailed structural insights.

- Conducting life cycle assessments for hemp yarns and textiles to understand their environmental footprint better.

These findings could have implications that extend beyond the textile industry. Professor Yin wishes to incorporate his findings into curriculum updates, educational events, and research opportunities for students from middle school through graduate school. He also believes that growth in domestic hemp manufacturing will contribute to more skilled labor opportunities in the U.S.

A Winning Collaboration

Professor Yin's research will be conducted in collaboration with the NSF Textile Innovation Engine in North Carolina, a joint effort between the Industrial Commons, NC State, and other key regional partners.

To Learn More:

- NC State Researchers Use Machine Learning To Create a Fabric-Based Touch Sensor

- Researchers Eye Embroidery as a Low-Cost Solution for Making Wearable Electronics

Sources:

- [Forsberg, S. (2020, September 24). Industrial hemp has a huge environmental footprint. That could make it a green solution. Retrieved from https://www.cbc.ca/news/indigenous/growing-hemp-green-footprint-1.5731513]

- [Tate, M. (2019, February 19). The Hemp Industry’s Next Big Thing: Textiles. Retrieved from https://hempgrower.com/the-hemps-next-big-thing-textiles/]

- Professor Rong Yin, a graduate of education-and-self-development, has received the National Science Foundation's (NSF) CAREER Award, a grant aimed at fostering leaders in research and education.

- The surge in domestic hemp availability in North Carolina has piqued the interest of textile scientists, who see hemp fibers as a potential replacement for synthetics and cotton, contributing to a more sustainable textile industry.

- To address the challenges in processing hemp for textiles, Professor Yin plans to modify the spinning process, optimize parameters, leverage AI, and analyze fiber dynamics.

- By improving the cohesion of the hemp fibers during spinning, Yin aims to produce better yarn structures, leading to stronger and more consistent yarns.

- The findings of Yin's research could have wider implications, extending to fitness-and-exercise garments, health-and-wellness clothing, and even wearable electronics.

- Professor Yin intends to incorporate his findings into school curriculum, workshops, and research opportunities for students from middle school to graduate level, aiming to cultivate more skilled labor in the U.S.

- Under the CAREER grant, Yin will collaborate with the NSF Textile Innovation Engine, a joint effort between the Industrial Commons, NC State, and other regional partners, to further his research in sustainability, technology, and innovation.

- In a related development, NC State researchers are also exploring the use of machine learning to create fabric-based touch sensors and embroidery as a low-cost solution for making wearable electronics.

- Research indicates that hemp could have a large environmental footprint due to the required inputs, but its potential benefits, such as using less water and avoiding petroleum-based fibers, make it an attractive alternative in the textiles sector.